Short block

Last night I went back and tore down everything, so first thing this morning I went to NAPA to have the stud Healy-coiled. $35 later my case is ready to start over.

Yesterday I also went to Wessex Motors to ask if they had a distributor drive shaft shim, since I had too much clearance between the shaft and the case. He called me back today and said he had found one in a box of old VW parts and gave it to me. There were a few campters, a Karman Ghia (he said the engine was being rebuilt as a father-son project by a friend, it looked really good), and a little Porsche at Wessex. Its always interesting to see other VW.

I was confused about installing the distributor drive shaft in relation to the distributor gear on the crank and I posted at TheSamba about it and it turns out that it doesn't really matter how it goes in! I spent a good two hours figuring that one out.. but that was yesterday before the stud stripped out.

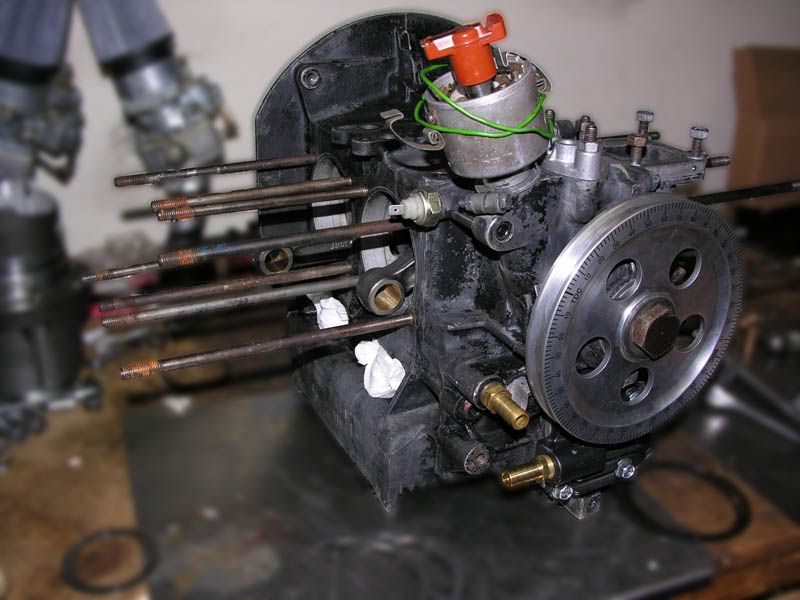

Today, after I cleaned everything out, I began assembly and it took no time at all.. I'm a pro at it now. First the distributor drive shaft, then bearings and crank, then the lifters and cam and then the other half of the case. Everything needs to be really lube'd up and one half of the case needs liquid gasket coated on since there are no case gaskets. By mid-day it was all bolted up and torqued down.

Next was to set the end-play by putting on the fly-wheel, torquing it to 200 foot-pounds and measuring the movement when you push/pull the fly-wheel. When I put all three shims on (.030 of an inch) it was so tight that there was no end-play and the crank wouldn't turn. I left only one shim (.010 of an inch) on this time but the end play was excessive. I put two shims on (.020 of an inch) and, just by eye, the end play seems good. Specifications say that it needs to be between .030-.050 of an inch so I will need to measure how much end play I actually have with a dial-indicator and then add what ever shims I need, meaning I had to order a set of shims.

Next I put the pulley on, then the oil strainer and plate, then the oil pump and the new pump cover made for 'full flow'. It's coming together!

I need to set the deck height by mocking up the piston and cylinder and seeing how much I have so I can add the appropriate shims. I expected that I would have the correct deck height with the shims I was given, but when I mocked it up the piston was flush with the cylinder top meaning I had no deck height. I need a .040 shim under all the cylinders to get the right deck height. A .040" deck height and 53ccs of volume in my heads will give me a compression ratio of 9 to 1. I will need to order the shims so it looks like I have the weekend off.

here is all that I've gotten done today..

0 Comments:

Post a Comment

<< Home